Spring return angle travel electric actuatorbelongs to the mechanical storge class ofactuators,under normal power supply, theactuator is driven by the motor to open thedevice at the same time the spring energystorage,the system emergency powerfailure, the spring releases the energy todrive the actuator, so that the equipmentand devices to return to the safeposition(fully open or fully closed). Theprocess is safe and smooth, to avoid causingpipe burst(water hammer phenomenon).

The intemal mechanical components of aspring-return electric actuator include adrive unit, an energy storage unit, and anenergy locking unit. These three units form acomplete transmission chain system throughgear transmission.

Additionally, an optional manual operationdevice allows users to manually adjust theequipment or device to the appropriateposition and lock it by pressing the lockbutton. During electric operation, no manualunlocking is required.

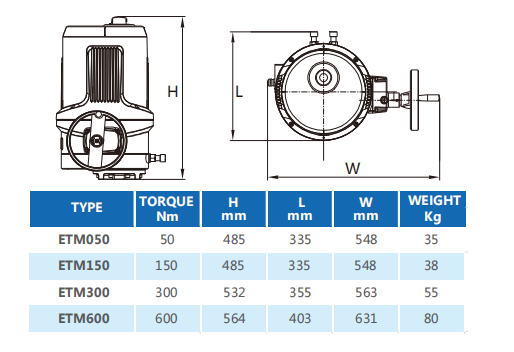

PRODUCTION DIMENSION

Compact design with a small footprint.

NO PERIODIC MAINTENANCE

Requires no periodic maintenance and ensures long-term trouble-free operation. The spring efficiently drives a full 90° travel, with slow closing during emergency valve shutoff (or opening) to prevent pipeline impact.

POSITION INDICATION

The travel limit switch is simple and reliable to set, with a 3D indicator allowing multi-angle visibility of the switch position. Options include digital (switch) or analog control.

SAFE OPERATION

In emergency situations requiring safe valve opening or closing, this product delivers the highest level of reliability through a mechanical solution. As needed, the spring-return electric actuator generates the required torque via an energy storage mechanism, enabling automatic return to position throughout the spring-return operation without any intervention.

ADJUSTABLE RETURN SPEED

The return speed of the spring-return mechanism is adjustable. The actuator can reduce the operating speed and drive the valve to the preset end position, thereby preventing sudden pressure surges in the pipeline and effectively protecting both the valve and the pipeline system.

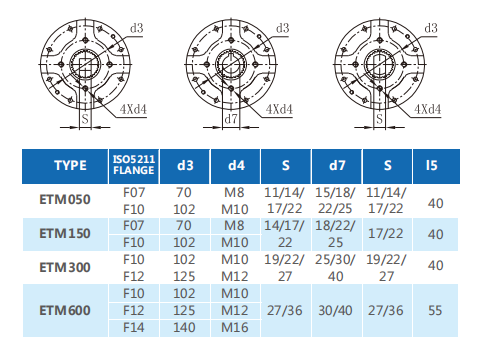

REPALCABLE CONNECTIONS

The actuator's flange and drive sleeve are designed in compliance with ISO 5211, with multiple interchangeable configurations available for enhanced flexibility and adaptability

DIMENSIO

CONNECTIONS

Next :

Explosion Proof EXB Series